Quality Assurance

Quality Assurance

Design & Engineering Mold Manufacturing Injection Molding Secondary Processing Quality Assurance

As a company committed to excellence and responsibility, we are guided by our fundamental principle of zero-defect. That is why we respect and value ambitious quality management as a crucial work step that completes the entire process and guarantees the expected quality to the client. We employ systematic process monitoring and initiate quality analysis from the very beginning of the design process. Our activities are also checked regularly by certifications in accordance with ISO9001:2015 & IATF16949:2016, as well as audits of our clients' processes and systems.

|

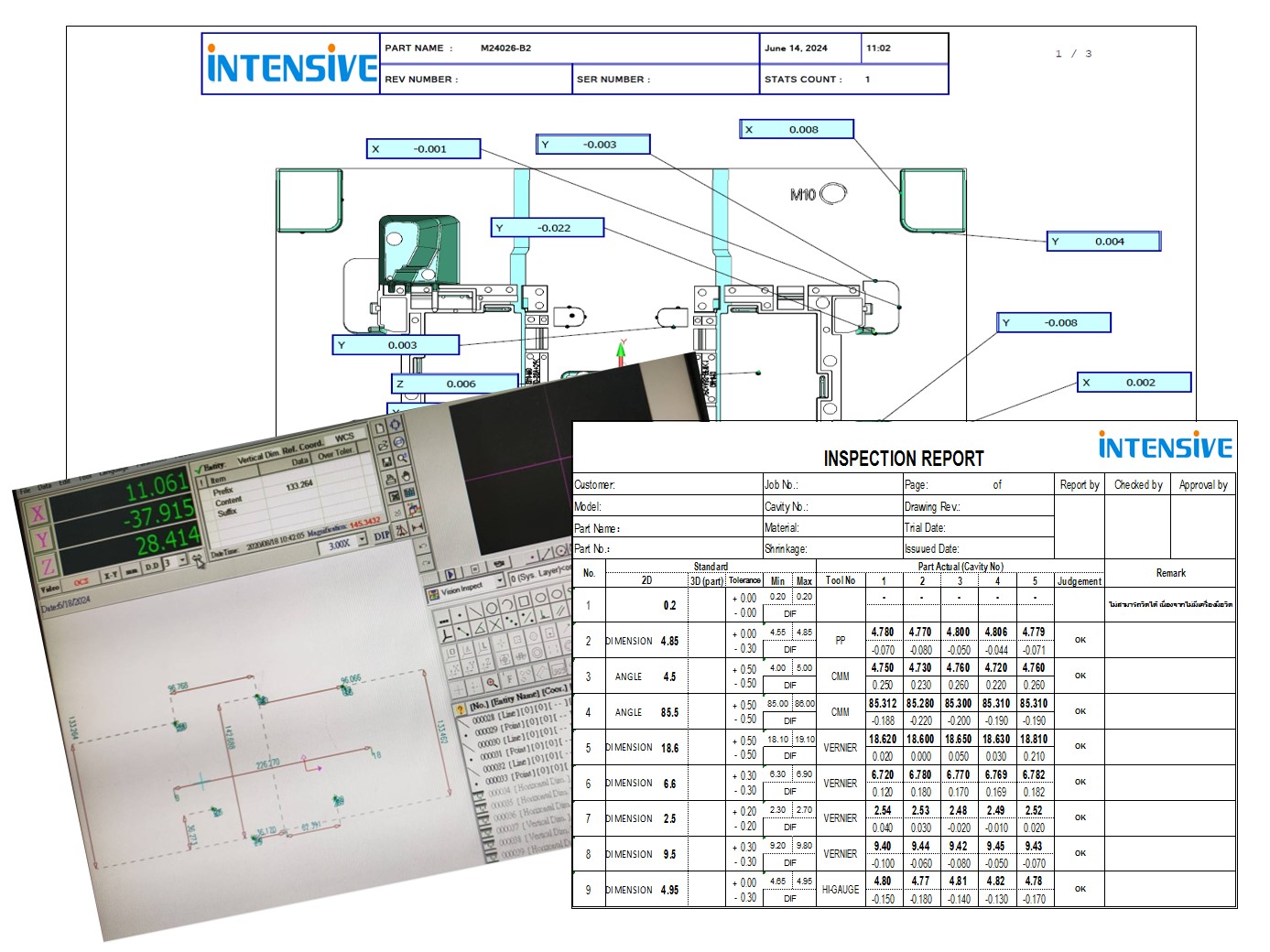

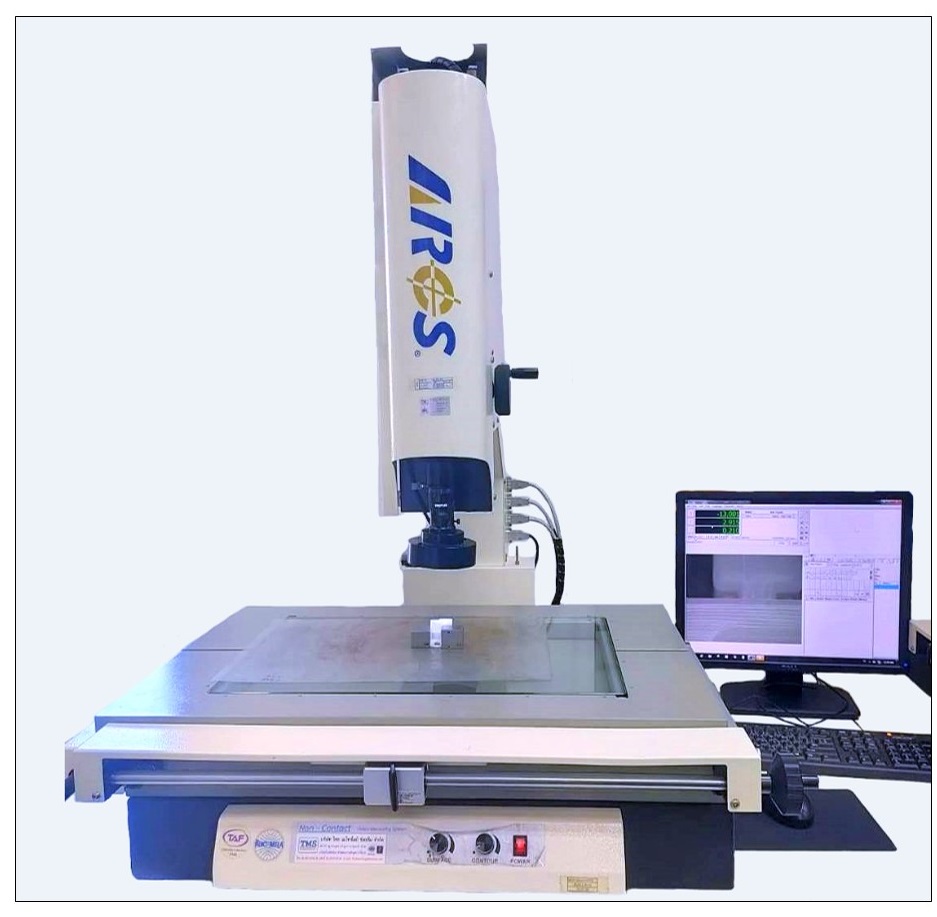

Mold Main QA Procedures: ■ Moldbase inspection |

Plastic Injection Control Process: ■ Conducting first-article inspection of critical dimensions, compared with approved samples |

| 1. IPQC regular inspection | 2. Timely guide and deal with abnormal production quality | 3. Staff Standard Work and Training |

4. OQC inspection and storage |

.jpg) |

|

.jpg) |

.jpg) |

.jpg)

.jpg)

.jpg)

03 July 2024

Viewed 196 times

EN

EN